The Challenges of Determining r & n Value

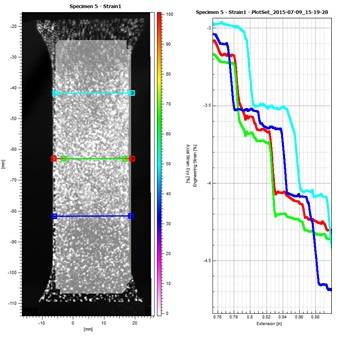

Extensometer Attachment

The results will vary depending on the location of the extensometer on the specimen. Shown in the image is a specimen with 4 different transverse gauge lengths using Digital Image Correlation Software. The effects of the extensometer attachment gives different transverse strain values. This would cause a difference in the r-value calculation. Manual placement of the extensometer will influence the transverse strain measurement.

Specimen Alignment

Sheet metals are sensitive to the direction in which they are pulled in tension. Using specimen alignment tools/fixtures will reduce the variation of the test results.

Specimen Measurement

Typically, materials are measured using micrometers. Width and thickness measurements should be taken at multiple locations across the specimen and averaged. The technique of measurement between operators can cause variation and may effect the r-value if it is based on the original widths measured by the operator and not of the width measured by the extensometer.

Specimen Preparation

Poor specimen preparation can be a reason for variation in test results; r-value is very sensitive. The specimen needs to have ‘smooth’ edges. If the edges are jagged where transverse strain is measured you will see a wide variation in r-value. Additionally, specimens that are bent, twisted, or bowed can cause variation in test results.

Specimen Strain Rate

As some metals are strain rate sensitive, the calculations for r and n values can vary depending on the strain rate. Keeping a test in consistent strain control will be the optimum control parameter, ensuring the changeover in speed during the test is optimized.

Thermal Effects

Sheet metal specimens can be affected by thermal transfer during manual handling or from the extensometer. Using gloves during specimen installation eliminates thermal transfer effects, improving repeatability. Materials used for any contacting extensometer must be optimized to ensure thermal transfer from the knife edges does not affect the results. Alternatively, using non-contacting extensometers eliminates this effect.