Precise measurement of specimen dimensions is critical for obtaining accurate stress and modulus results, but the typical specimen measurement process can be time consuming and prone to data entry errors.

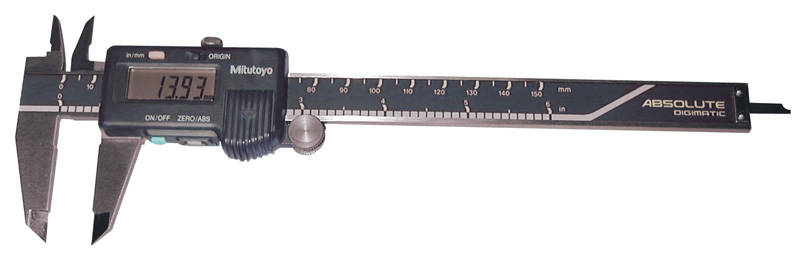

The specimen measurement process usually requires the operator to take the dimensional measurements of each specimen with a handheld caliper or digital micrometer, and then manually input that data into the testing software. Depending on the testing standard, the operator may be required to take multiple readings of each dimension; for example, at three different points on the specimen’s width and thickness.

Manual data entry is always vulnerable to error, so this method of specimen measurement carries with it a certain level of risk that bad data could enter your data set and affect your test results.

The good news is that if you use Bluehill® Universal, Bluehill 3, Bluehill 2, Partner™, Merlin™, or Series IX™ there is a very simple solution that can speed up this process and eliminate the risk of data entry errors.

All you need is a compatible digital micrometer or caliper that has the automatic data entry interface. Plug this into your Instron testing system, and the testing software will recognize the device and allow you to use it to record your specimen dimensions. With the micrometer connected, simply measure your specimen dimensions as usual and then click a button on the micrometer to send the digital measurement directly to the software – allowing you to skip the manual data entry step entirely. If two devices are required – for instance, one for the width measurement and the other for thickness – an interface box can be included to connect both for simultaneously usage.

These micrometers can also be configured with a footswitch, allowing you to enter the specimen dimension into the software by tapping the footswitch.

In Bluehill software you can also set the required number of readings. In the example shown above, we have set it to require three readings for both the specimen width and thickness. In addition, the reported results of the readings are configurable to report the average, minimum, maximum, or median.