8 Tips for Safe Testing with Instron® Universal Testing Machines

The following are sometimes overlooked safety features of your Instron test system. Following these procedures can quickly add real safety improvements to your lab. Please read your Manual and Operator’s Guide for a full list of all safety precautions and instructions.

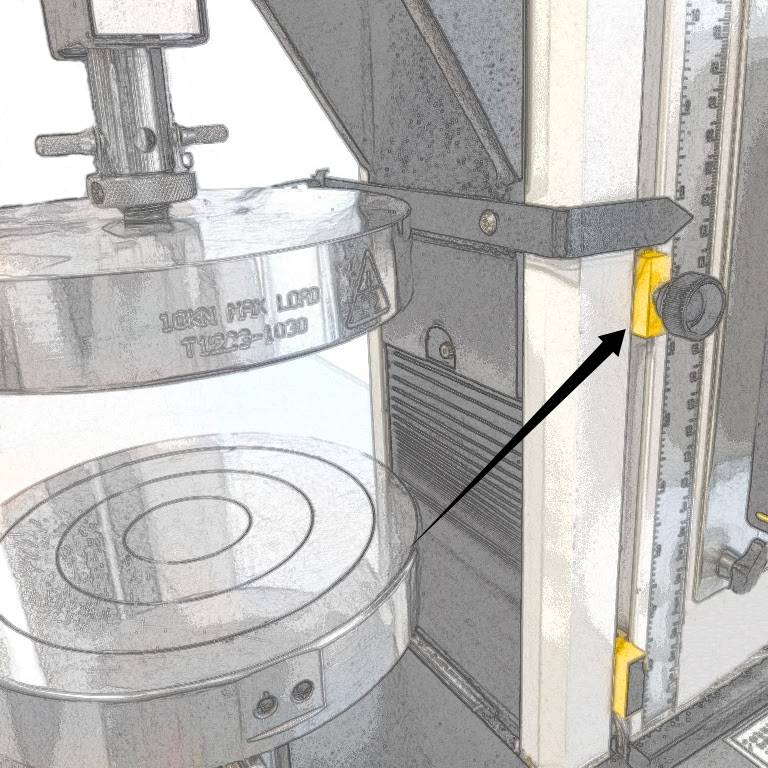

1) Set Crosshead Travel Limits

Adjust the upper and lower travel limits on your system every time you change the grips and adjust the crosshead. Bring the crosshead down to the lowest position that you ever want it to go and set the limit at that point. This will ensure the crosshead never goes lower than this position reducing the potential for a crush or pinch hazard, or damages your grips or fixtures.

2) Keep Clear of Small Gaps

Small test specimens often require small gaps between grips and compression platens. Avoid putting your fingers or hands in small gaps when loading specimens. Use tongs, forceps, or a hemostat to load your specimens instead.

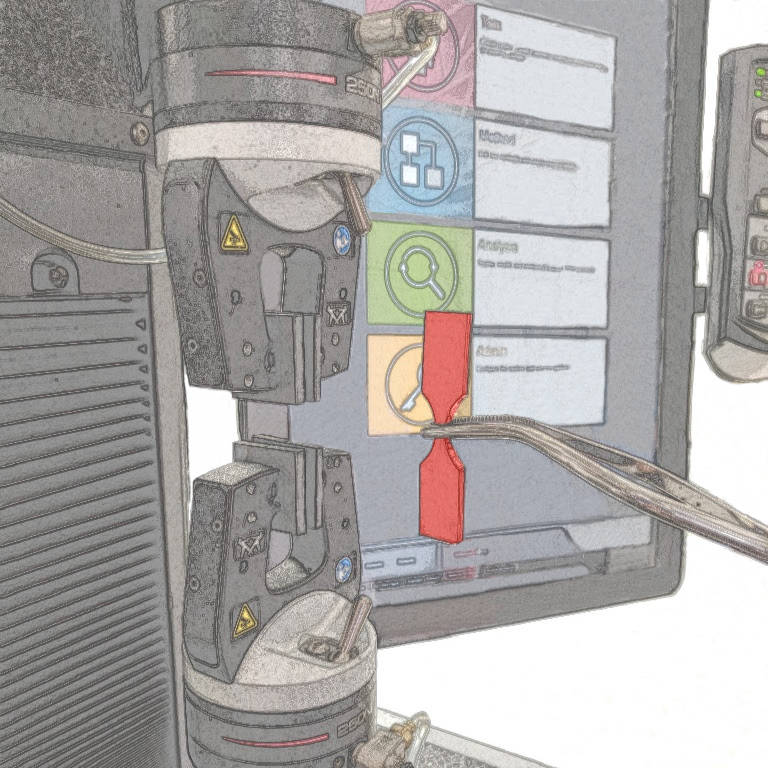

3) Slow the Closing Rate of Pneumatic Grips

Instron 2712 Series pneumatic grips have a screw located at the air hose connection that adjusts the speed of air flow to the grip. You can tighten this screw to reduce the speed of closing. Adjust the screw until you find a comfortable closing speed.

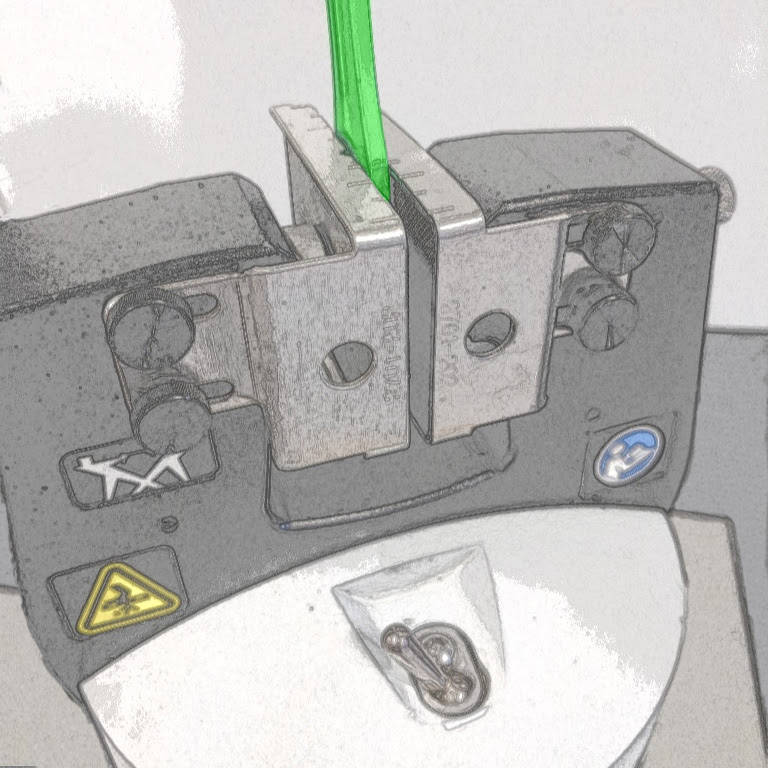

4) Use Pneumatic Grip Jaw Face Shields

Jaw face shields attach to your 2712 Series pneumatic grips and cover the gap between the jaw faces to reduce the possibility of a finger pinch. Instron 2712 Series pneumatic grips include jaw face shields for the most common jaw face sizes. Jaw face shields have center marks to assist with specimen alignment in the grips. Check HERE for additional sizes.

5) Reduce the Jaw Face Gap

2712 Series pneumatic grips in 1kN, 2kN, 5kN, and 10kN capacity have thumb screw knobs on the sides of the grip. Use these knobs to bring the jaw faces close to the thickness of your specimen. This reduces the possibility of a finger pinch. See how it's done HERE.

6) Don’t Forget the Clevis Pin Clip

Most Instron grips and fixtures attach to the system with a simple clevis pin. In very rare cases, perhaps during cyclic testing, the clevis pin could slide out, risking a grip or fixture becoming unsecured to the system. To prevent this, use the clevis pin clip supplied with your system to make sure this does not happen. It is also important to make sure the check nut supplied with the pin and clevis connection is tightened against the load cell and the base of the machine to prevent unnecessary movement of the grips during testing.

7) Use a Debris Shield

If your testing requires a debris shield, you probably already have one in your lab. However, not everyone uses a shield who should. Composites, plastic flex samples, and cargo straps are a few examples of materials that can explode, shoot out of the grips, or become projectiles upon specimen failure. Personal protective equipment (PPE) should be used in these cases as well as a debris shield. Instron offers optional debris shields for all systems.

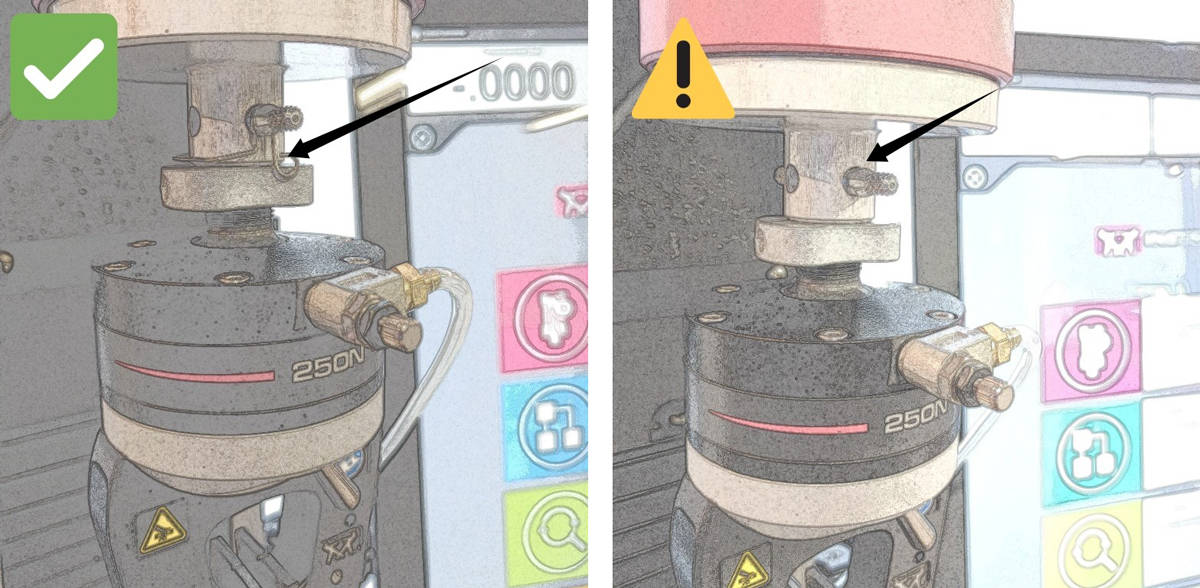

8) Use Specimen Protect

Specimen Protect is a standard feature on all current 5900 Series systems, and 5500 systems. Specimen Protect limits the maximum force applied to the test specimen when not running a test. When enabled, the crosshead moves up and down automatically, usually in small amounts, to ensure the force reading on the load cell remains within the pre-set force bounds. It is often used to protect specimens or components once they are gripped during set-up, so as not to apply an accidental tensile or compressive force to them before testing.

Have Questions?

Contact Us