Instron® Introduces AverEdge32™ for AVE 2

Advanced Averaging Transverse Strain Measurement Technology for Sheet Metal

Built on our trusted AVE 2 Advanced Video Extensometer, AverEdge32™ is Instron’s latest innovation in providing best-in-class transverse strain accuracy for all sheet metal materials.

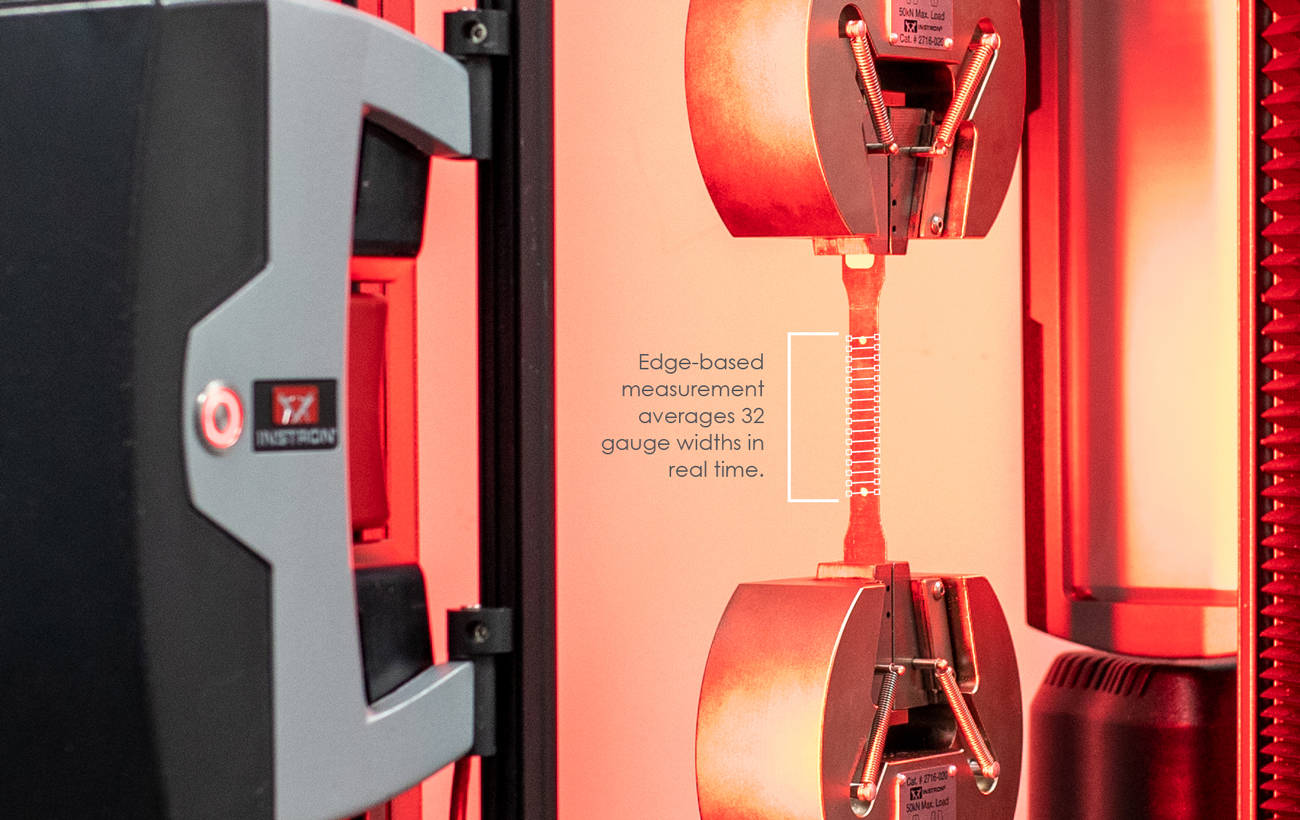

AverEdge32 is an optional advanced feature of the AVE 2 that utilizes edge-detection technology to simultaneously measure transverse strain at 32 locations along the specimen gauge length. It then averages them in real time, resulting in a smooth and repeatable transverse strain value, which is essential to calculating the plastic strain ratio (r-value) of sheet metal.

With the ever-increasing importance of vehicle lightweighting, formability testing of sheet metals, especially aluminum and high-strength steel, requires accurate and repeatable transverse strain measurement. This is particularly important for calculating the r-value, which can be greatly impacted by small errors in strain.

Materials that exhibit discontinuous yielding and/or the Portevin-Le Chatelier (PLC) effect, produce noisy or inconsistent transverse strain data when measured at a single gauge width. AverEdge32 solves this dilemma and has shown up to 20x reduction in variability, resulting in r-value results with sub-5% variance, similar to other material properties such as yield strength.

This capability can be easily added to any existing AVE 2 without affecting any other existing capabilities, providing a simple upgrade with minimal downtime or risk. It also eliminates the need for transverse marks on the specimen.

Improving repeatability of the r-value is one major benefit which encompasses several others. Repeatable results can allow a manufacturer to set better expectations with their customer, which improves confidence in the product and benefits the reputations of both companies. Improved repeatability also eliminates the need to retest specimens, which also means reduced test times, reduced waste, and elimination of production stops, which allows product to ship on time and ultimately reduces cost.