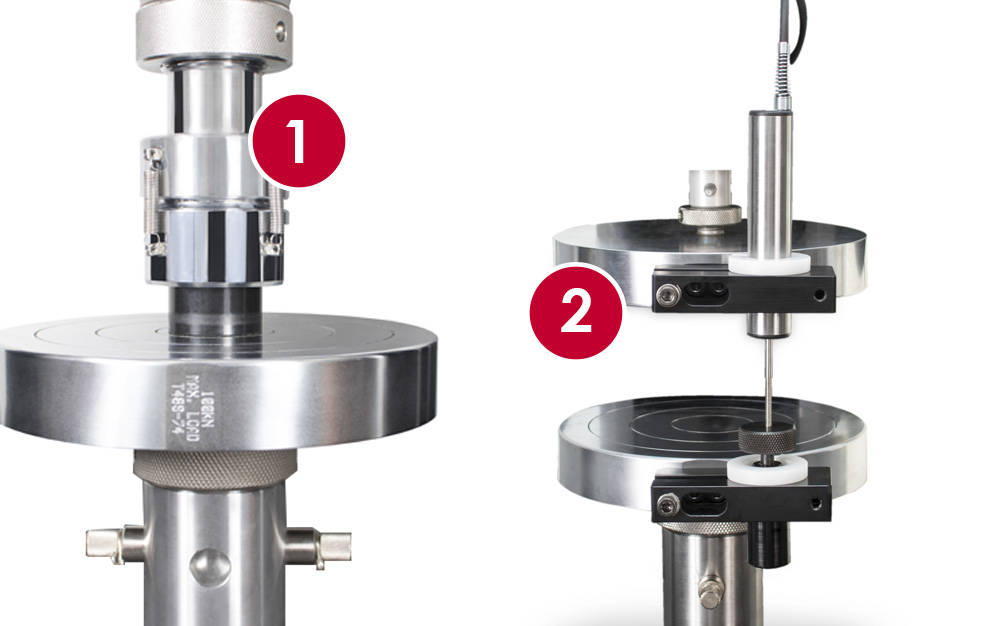

ASTM D575-91: Standard Test Methods for Rubber Properties in Compression

Related Content

最高クラスの6800シリーズ試験機のカタログ

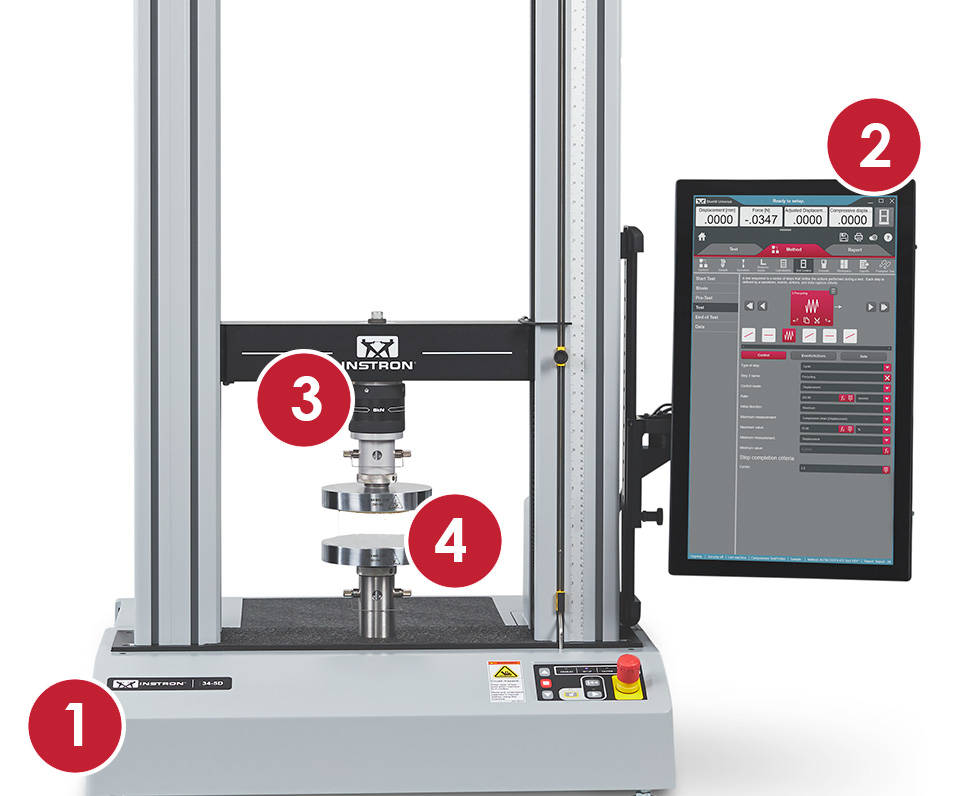

インストロン6800シリーズ万能材料試験機は、他に類のない精度と信頼性を提供します。特許申請中のオペレーター保護機能に基づき、最新のスマートクローズエアキットおよび衝突緩和機能を搭載した6800シリーズは、材料試験をかつてないほどシンプルに、スマートに、安全にします。

Bluehill Universalのカタログ

Bluehill Universalソフトウェアは、タッチ操作と直感的なユーザーエクスペリエンスを念頭に構築されています。標準装備の試験メソッド、数秒で行われるQuickTest、強化されたデータエクスポート、そしてサービスとの直接通信を提供する新機能Instron Connectなどの機能が、これまでよりもシンプルでスマートな試験を可能にします。Bluehill 2やBluehill 3などの旧バージョンソフトウェアからは、簡単に最新バージョンのBluehillにアップグレードできます。