KIc Fracture Toughness to ASTM E399

- Metals

- ASTM E399

- ISO 12135

- Fracture

Written by Dr. Peter Bailey

High strength metals can often fail in a surprisingly brittle manner, especially if a component is overloaded where a small crack is already present. Resistance to localized failure (as opposed to bulk tensile strength) is generally described by the umbrella term of fracture toughness. Within that KIc is a parameter for the critical stress intensity, above which sudden catastrophic failure can be expected.

Most prevalent use is in aerospace applications, where highly controlled standardized testing is expected; ASTM E399 is popularly used, but equivalent methods are provided by ISO and British Standards. The KIc fracture toughness test provides end users, as well as alloy developers and producers, with a metric for material performance and quality control in critical applications.

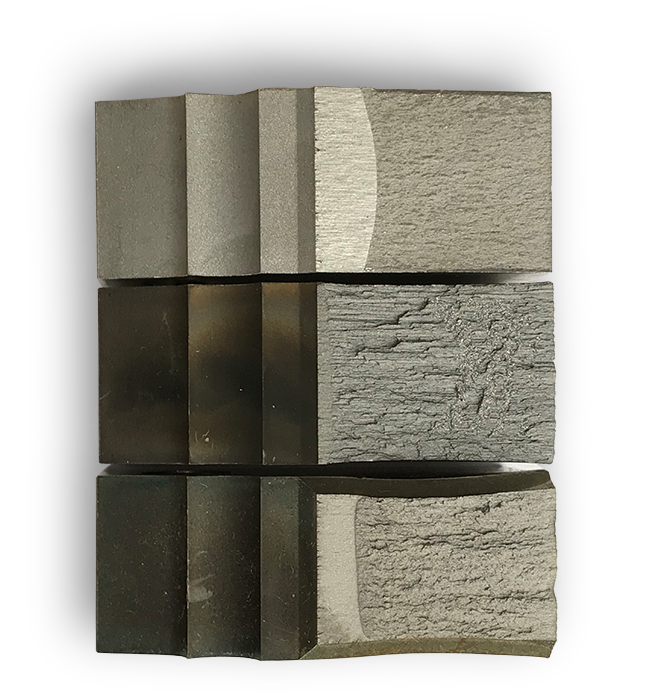

Each test piece must initially have a real crack grown from the notch, using fatigue (cyclic) loading, in order to provide a truly “sharp” line from which failure will be initiated. Typically, this precracking process will take at least 30 minutes, but may be much longer depending upon material and equipment performance. The main test itself is then a simple, slow loading ramp, until the crack suddenly or rapidly grows across most or all of the remaining width of the specimen. The specimen is then separated and the exact length and shape of the initial crack is measured to enable accurate calculation of the critical stress intensity from the recorded force at which failure occurred.

With good test equipment and specimen manufacture this does not need to be a difficult test to perform. However, results could easily be skewed by a range of factors, so international test standards are highly prescriptive for a range of criteria designed to ensure comparable results between specimens, batches, or laboratories. ASTM E399 in particular, has at least 13 validity checks which must be satisfied to declare a comparable value of KIc and has moved to recommend the use of specific automated algorithms for data analysis (see ASTM E3076).

Bluehill Fracture is designed to provide a clear workflow to support this, with options to make streamlined and automated test routines for quality control environments. It also provides high flexibility for research users, as well as detailed break-down of validity checks and intermediate results should a result fail to meet the standard requirements. Where researchers or contract test houses need to provide results in several forms, existing datasets can be re-opened and instantly re-analysed to alternative international standards, presented in different units (e.g. swap from metric to US customary), or exported to alternative report templates. The software implements all recommended techniques and is routinely updated to reflect latest revisions to the supported standards of ASTM E399, ASTM B647, ISO 12135, BS 7448-1.

The long standing BS7448-1:1991 was formally withdrawn by the British Standards Institute in August 2021, to be superseded by BS EN ISO 12135:2021. Bluehill Fracture continues to support BS7448-1 analysis for those customers who need comparability of new tests with legacy data.