Below you will find answers to the most frequently asked questions for composites testing.

How can I improve my productivity when I frequently need to change the test setup for our universal testing system?

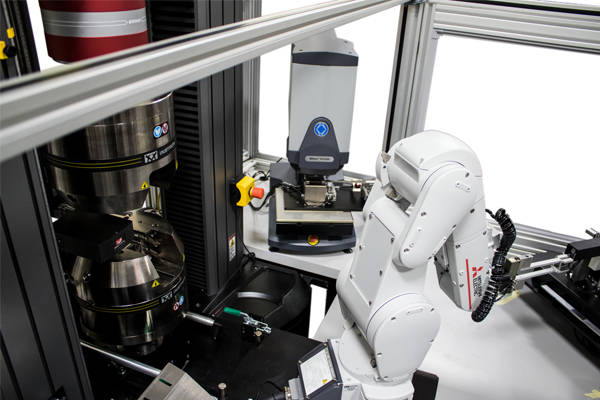

Many of our customers require multiple different test setups. One option to increase productivity in this instance is to purchase a second test frame with the specific setup you desire. However, this will be expensive and may not be needed, as many of our grips can be equipped with adapters to “piggyback” smaller load cells or accessories of completely different test setups and load ranges, expanding the capabilities of a single system. For even greater throughput and repeatability with different test setups, Instron also offers complete automated solutions like the AT3 or AT6 robotic testing systems. Bluehill® Universal software includes pre-built test methods for many common testing standards, making it simple to configure new methods once your test setup has been changed.

Example of "piggybacking" compression platens to a system equipped with hydraulic wedge action grips.

How can I interface strain gauges to my Instron machine?

Our strain gauge adapters make it easy to connect strain gauges to a standard Instron strain channel. These adapters mount directly to the T-slot of your Instron test frame and incorporate simple spring-loaded terminals. Both two and three wire strain gauge connections are supported. The adapter is compatible with strain gauges with gauge factors between 1.5 and 2.5, and you can connect as many of these as there are strain channels available.

For tests with more strain gauges we offer our Expansion Channel Module, which can be used to connect up to 8 additional strain gauges for a total of 11 strain gauges at one time on your Instron test frame. The Expansion Channel module comes with features such as adjustable data sampling rates, automatic recognition and electrical calibration of Instron load cells and extensometers, fully-synchronized data acquisition and logging across all machine sensor channels, and test control across any channel.

How can I be sure that my testing machine alignment will be sufficient for a Nadcap audit?

The very solid design of our test frames in combination with high precision manual or hydraulic grips ensures minimal compliance and bending, achieving Nadcap alignment requirements without the need for an alignment cell. For more complex test machine configurations, the same system can easy be configured with an alignment cell and software to minimize bending. Our Service team can perform such an alignment on your frame to ensure that you are complying to Nadcap bending requirements on your next audit.

Can I perform a low force interlaminar shear stress test and a high force tensile test on the same machine?

The combination of Instron-designed load cells and Instron advanced digital electronics on properly configured Instron test systems allows your setup to achieve accuracies of +/- 0.5% over a range of 1000:1 This eliminates the need to change load cells in the majority of testing situations, e.g. when switching from a high force tensile to a low force shear stress test.

Instron load cells are individually compensated and tested to ensure that they have a temperature coefficient of less than 0.001% of full output / degree C. Instron’s deadweight stack plays a critical role in the production of calibration standards that are used to verify working load cells at these types of enhanced accuracies and ranges.

I currently test to ASTM D3039. In the future, I may need to test to ASTM “XYZ”. How can we future-proof our materials testing equipment?

Instron’s universal testing machines have standardized mechanical interfaces which can be connected to many different grips, fixtures, and accessories. If you are about to purchase a new system our sales engineers will take your future needs into consideration when recommending the appropriate setup. If you already own an Instron system, you can simply purchase additional accessories and fixtures for your future testing needs.