Extensometers measure the amount of strain a specimen exhibits during a materials test. They are typically used when testing in tension, but can also be used when testing in compression and flexure. Measuring directly at the specimen eliminates any other sources of compliance or deflection in the load string and load cell in order to provide the most accurate measurement possible.

When determining the best extensometer for your application, the most basic information needed is the gauge length and total elongation of your specimens, but there are also other, less obvious factors to consider.

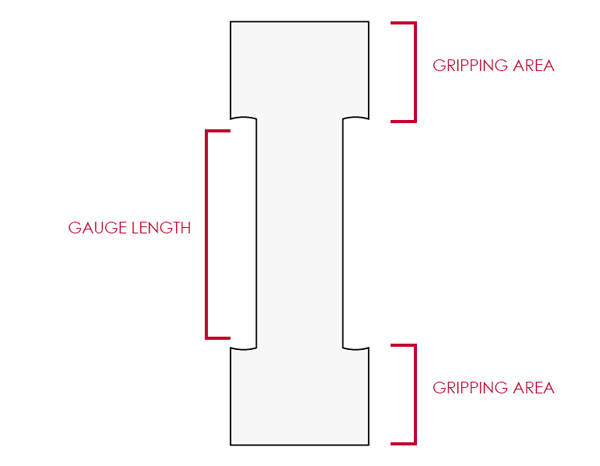

The “gauge length” (GL) is defined in ASTM E6-15e4 Standard Terminology Relating to Methods of Mechanical Testing as ”the original length of that portion of the specimen over which strain or change of length is determined.” For the familiar dog bone specimen, the gauge length will be within the reduced parallel section. The size of the gauge length will typically be defined or suggested by the test standard.

“Strain” is defined as “the per unit change in the size or shape of a body referred to its original size or shape.” “Elongation” is more specifically the change in gauge length due to tensile force, expressed as a percentage. If the gauge length starts at 1 inch and elongation is 100%, then the length of the specimen in the gauge length has increased by 1 inch.

The type of material and any test standard requirements will help focus your search for the right extensometer. The “class” or required measurement accuracy is typically stated in the test standard and will be different for materials that exhibit different stiffness (i.e. elastomers vs. composites or ceramics), expected elongation (10%, 50%, 200%, or greater than 1000%), or where certain results need to be measured (i.e. before yield vs. at fracture).

The design of many extensometers is driven by testing standards, but some extensometers are very flexible and adaptable to different materials or types of tests, so you may only need one to meet all your needs. But there are many times where a more specialized device is vital to the application (torsion, biaxial, high temperature, cyclic fatigue, etc.) and may only be suitable for specific specimens (due to size, shape, stiffness, etc.).

Other aspects to consider are the skill level or experience of the operators and how much turnover there may be in your lab. Do you need an extensometer that requires training and is dependent on operator skill and technique, or one with more automation capabilities that requires very minimal training? If the device is fully integrated with the test system and software, most operator errors can be prevented.

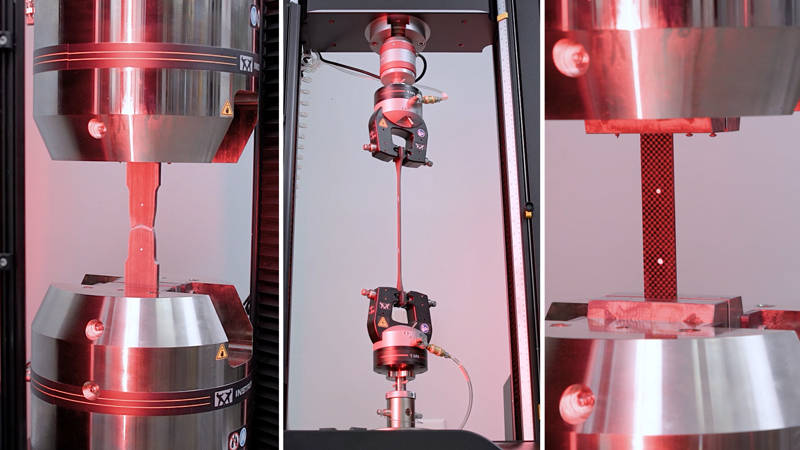

Extensometers come in two basic varieties: contacting and non-contacting. A contacting extensometer physically attaches to a specimen in order to measure strain. These devices usually have a defined gauge length, and some may incorporate a means for multiple gauge length options. Contacting extensometers exist for the entire gamut of material types from low strain composites to high elongation elastomers. A handheld “clip-on” style device is most common for nearly all tests below 50% total elongation, but these can also be removed during the test if expected elongation is above its design limit. Clip-ons are not always the best choice, however. For high-elongation materials (50% to 1000% or greater) a larger device that attaches to the test frame is necessary. Furthermore, materials that are delicate or very thin/narrow are not good candidates for use with clip-ons. Different measurement technologies are used where most appropriate, i.e. strain gages, LVDTs, rheostats, and digital encoders.

Non-contacting extensometers, on the other hand, do not need to physically touch the specimen in order to measure strain because they do this from a distance using highly sophisticated algorithms. The most common type of non-contacting extensometer uses digital image analysis to track marks applied to the specimen. Because these marks can be placed anywhere, these extensometers are not restricted to a specific gauge length. To make them even more versatile, they can also be used in conjunction with a temperature chamber for non-ambient testing, or with a fluid bath. Instron has been designing these kinds of devices since the 1960’s, and in 2004 brought the first all-digital video extensometer to market as the first-generation AVE.

Automatic extensometers require little to no input from the user, which helps provide repeatable and reproduceable results between different users and different labs. They also improve throughput by eliminating the time required to attach and remove them from the specimen. Automatic contacting extensometers, like the AutoX750 will move the arms to the pre-defined gauge length, close the arms on the specimen, then open the arms after the test is complete and position itself for the next one. Materials that exhibit high-energy breaks usually require the arms to be removed from the specimen prior to specimen fracture so as to avoid damaging the highly accurate instrument. Automatic non-contacting extensometers have the benefit of being safe from specimen breaks since they are far enough away from the test space, do not touch the specimen, and generally have no moving parts, allowing them to measure strain through fracture.

Choosing the right extensometer can be critical to your business, but it doesn’t have to be stressful or difficult. Your local Instron Applications Engineer can help take all the guesswork out of the process and quickly determine the best one for you and your testing needs. Contact us to learn more.

For more information check out our extensometers.