Composite materials made from a polymer matrix with carbon fiber reinforcements offer excellent mechanical properties, including strength and stiffness. They are also much lighter than metallic alternatives and are widely used in the automotive industry. However, composite laminates are vulnerable to damage caused by compression after impact that can result in a dramatic reduction of their strength.

The damage can affect all layers of the composite but may not be easily visible. Low energy impacts are often most dangerous because a visual inspection of the surface may not reveal any sign of damage. It is, therefore, vital to measure the effect of impact energies on the residual strength of a laminate composite. This is where a CAI test can help.

ASTM D7136 and Other CAI Test Methods

A compression after impact test has two parts, each defined by an ASTM international test standard:

- ASTM D7136 describes the requirements for using a drop weight impact testing machine to introduce a Barely Visible Impact Damage (BVID) to a composite laminate panel. A flat rectangular plate is subjected to a concentrated impact using a drop weight impact device with a hemispherical impactor. The potential energy of the drop weight impact is defined by the mass and drop height and is specified before the test.

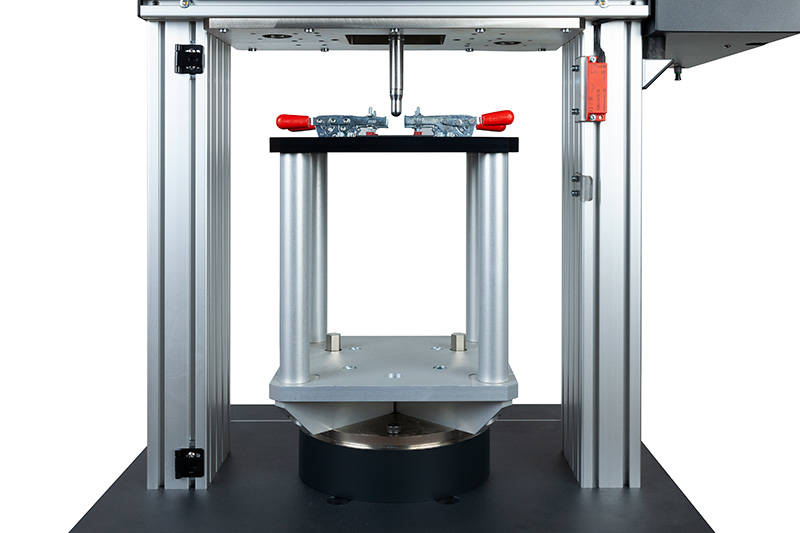

- ASTM D7137 describes the requirements for performing a compression after impact test on the damaged specimen by using an electromechanical machine to measure its residual strength. Properties generated by this method are highly dependent on specimen geometry, layup, damage type, damage size, damage location, and boundary conditions.

Other relevant CAI test standards include Boeing BSS 7260 Class II, Airbus AITM 1.0010, AITM 1.0076, AITM 1.0077, prEN 6038 and ISO 18352.

CAI Test Challenges

Because a CAI test is performed in two stages, consistency in the drop weight impact test is critical for the comparison of compression after impact results between different specimens. Impactor shape, impact energy and specimen support conditions can all have an impact on the accuracy of results.

Wherever there are manual interventions in the impact test apparatus setup, there is the potential to introduce slight variations in the test. This affects the repeatability of results thus decreasing accuracy. For example, slight differences in the dropping mass position and the release mechanism can both influence a CAI test accuracy. Another source of variation is friction coming from force sensors or tups and the impact test fixture, which come into contact with tower columns as they descend.

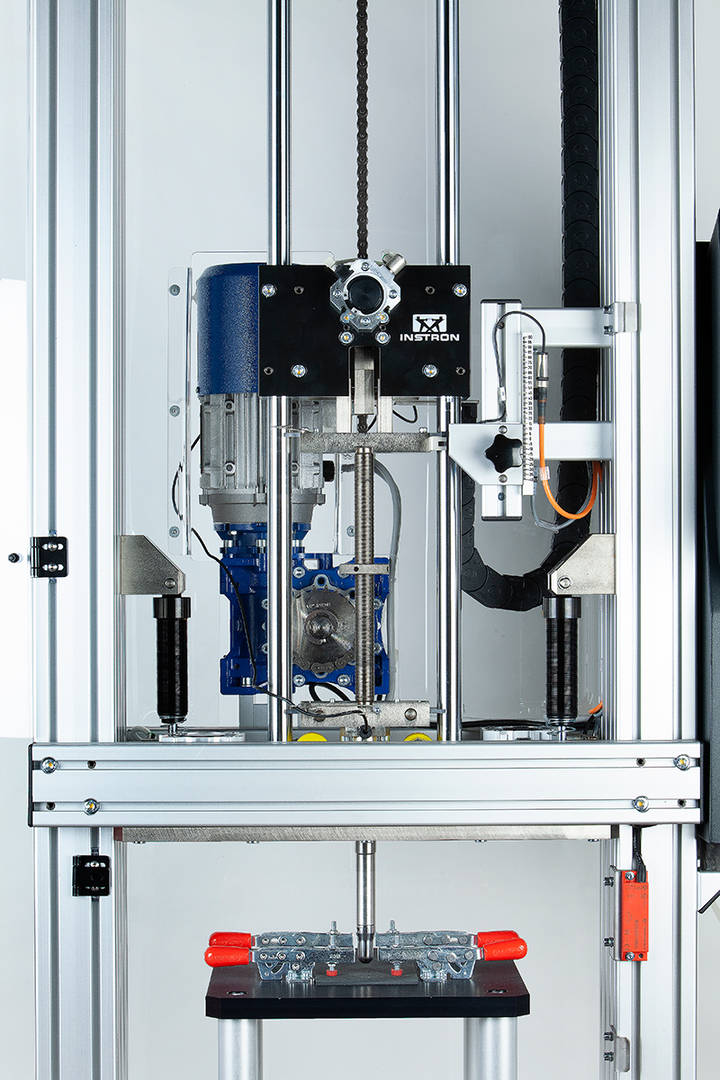

No secondary impact must occur during the drop weight impact test. Manual equipment may not be able to prevent the weight from falling back onto the specimen after the initial impact causing more damage than the initial impact alone. This is where the Instron 9400 drop weight impact testing machine comes in to help.

Improving CAI Test Repeatability and Reducing Operator Time

Key features of the latest drop weight impact test equipment which significantly improve accuracy for Compression After Impact testing:

- Instron drop weight impact machines also have automatic anti-rebound systems to catch the striker and prevent it from hitting the specimen a second time;

- Environmental chambers automatically condition a sample from -70°C to 150°C before testing, ensuring consistent sample conditions and repeatable tests.

Software control systems and user interfaces also simplify operator functions. Step-by-step instructions ensure that tests are always performed according to the correct standard method. The system produces impact curves and results tables immediately after each test giving the production environment timeous feedback on product quality. The Bluehill Impact software from Instron also alerts operators to calibration requirements and other parameters that may impact result accuracy.

Optimizing Operator Safety

Modern drop weight impact testing machines also have enhanced safety features. Safety switches on the turret and test area doors disable the system when one of these doors is open. This prevents operators from being exposed to moving parts during operation. Fan extractors are optional features used to prevent toxic fumes from escaping into the work environment where necessary. The software systems and user interfaces integrate equipment safety requirements so that the status of an instrument is always visible to operators.

Compression after impact is a key parameter to consider when assessing the performance of composite materials. The latest drop weight impact testing machine technology is the optimal impact test apparatus to perform a CAI test accurately, efficiently and safely.