Heat Deflection Temperature and Vicat Softening Temperature Testing

How to Maximize Throughput, Repeatability, and Safety

Heat deflection temperature (HDT) and Vicat softening temperature testing is critical to determining the quality and performance of polymers. As automotive components become increasingly lighter, there is a growing demand for high-performance polymers, which must undergo a thorough HDT and Vicat apparatus test process. Laboratories are under pressure to increase their throughput and deliver repeatable results while keeping lab technicians safe. Here’s how the latest HDT Vicat tester technology can help.

Key trends and challenges

The HDT and Vicat apparatus test is becoming commonplace in the automotive industry due to the rapid expansion of the high-performance and specialty polymers and composites market. Electric vehicles are driving this growth due to the need for lighter parts that reduce the load on batteries and allow for longer travel distances per charge. Some specialty polymer materials are used in the Li-ion battery packs too.

HDT and Vicat temperatures are critical properties for measuring the quality and performance of high-performance polymers:

- The HDT test for plastics measures the temperature where deformation occurs under a specified load;

- The Vicat apparatus test measures the softening temperature of a material.

Increasing HDT Vicat tester throughput

Manufacturers rely on HDT or Vicat test results for certifying products, and as such timeous results are critical to the production process. However, some materials have test results exceeding 200°C, which adds a significant heat-up and cool-down time for each test cycle. There are two main ways to improve throughput.

- New generation machines have highly efficient water coolers that can save up to 50% of the cooling time per cycle.

- Automating manual functions like the zeroing of the LVDT measuring sensors before starting a test reduces human error and set-up time. Pre-formatted ISO and ASTM templates and integrated touch screen interfaces enable operators to run tests in a few simple touches.

Maximizing repeatability in HDT Vicat testing

Repeatability is a vital concept in quality control for HDT Vicat testing. A repeatable test means that you will get the same result (within tolerance) when you run the test on the same sample. The silicon oil used for heating the sample can affect repeatability.

A low level of silicon oil in the bath can affect the HDT Vicat test results. This condition can be avoided by using an HDT Vicat testing machine that automatically checks the oil level before each run. When the system detects a low oil level, it alerts the user until the bath is refilled. This feature helps reduce the risk of running invalid tests while enhancing safety.

Oil quality can also influence the result. Suppliers issue guidelines regarding the acceptable number of cycles before the oil should be replaced, as the oil degrades over time. The latest HDT Vicat tester systems generate an alert when the oil is close to the recommended cycle limit to allow users to replace the oil before it degrades, thus ensuring the repeatability of results.

Testing high-performance materials at high HDT and Vicat softening temperatures

Traditional HDT Vicat test methods use silicon oil as the heating medium, but silicon oil has a high-temperature limit of 300°C. This temperature is not high enough to test new families of materials known as techno-polymers, which have HDT values of up to 500°C.

Aluminum oxide is an alternative heating medium for high-temperature applications. HDT Vicat testing machines use Aluminum oxide in a fluidized bed as a powerful medium to reach the 500°C required for new polymers. Unlike silicon oil, the material does not release fumes that can be dangerous to human health. It also remains stable over time, which reduces the need for regular replacement.

Optimizing safety during HDT Vicat testing

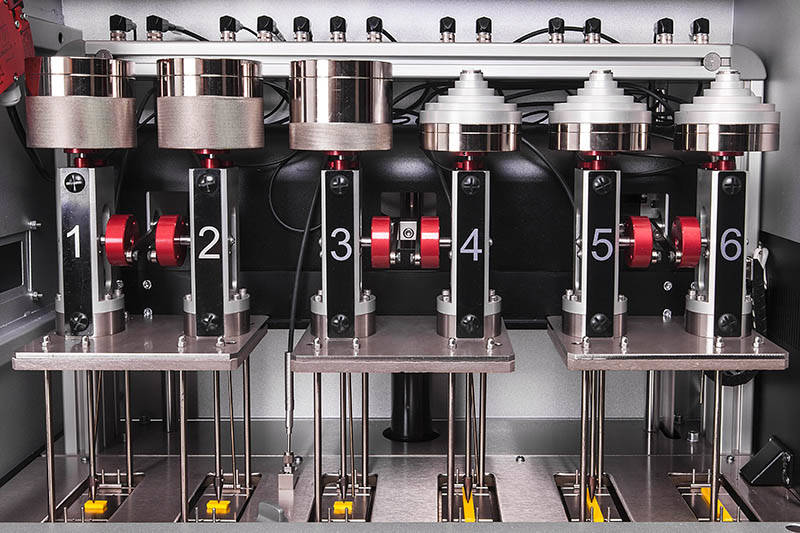

Burns and exposure to toxic fumes are two of the main safety hazards associated with HDT Vicat testers. Safety automation systems significantly reduce risks by preventing access to the heat bath and moving parts during operation. Fully enclosed test areas and pneumatic systems lower the stations at the beginning of a test and raise them once complete.

Ergonomics is also a factor in high throughput applications like HDT Vicat testing. Repetitive tasks and unnatural positions can cause long-term musculoskeletal issues. Machine design can limit these conditions by eliminating overhead movements and using guidance columns to make lifting and lowering actions smoothly. Safety features ensure that both hands are used to facilitate good control over these actions.

Conclusion

HDT and Vicat tester technology is developing to keep up with the demands of the polymers industry. Automation and safety features are saving time and reducing technician risk, and new materials like Aluminum oxide make it possible to test HDT Vicat at temperatures of up to 500°C. The latest HDT Vicat testing machines enable laboratories to achieve the throughput, repeatability, and safety requirements of the industry.

For more information download our e-guide.