ASTM D3410 - Measuring the Compressive Strength of Polymer Matrix Composites

最高クラスの6800シリーズ試験機のカタログ

インストロン6800シリーズ万能材料試験機は、他に類のない精度と信頼性を提供します。特許申請中のオペレーター保護機能に基づき、最新のスマートクローズエアキットおよび衝突緩和機能を搭載した6800シリーズは、材料試験をかつてないほどシンプルに、スマートに、安全にします。

複合材料試験のカタログ

インストロンの万能材料試験機は、複合材料業界で用いられる一般的なタイプの試験を行えるよう設計されています。具体的には、面内引張、厚さ方向引張、層間せん断、端末負荷圧縮、せん断、または複合荷重、および衝撃後圧縮などが含まれます。

Bluehill Universalのカタログ

Bluehill Universalソフトウェアは、タッチ操作と直感的なユーザーエクスペリエンスを念頭に構築されています。標準装備の試験メソッド、数秒で行われるQuickTest、強化されたデータエクスポート、そしてサービスとの直接通信を提供する新機能Instron Connectなどの機能が、これまでよりもシンプルでスマートな試験を可能にします。Bluehill 2やBluehill 3などの旧バージョンソフトウェアからは、簡単に最新バージョンのBluehillにアップグレードできます。

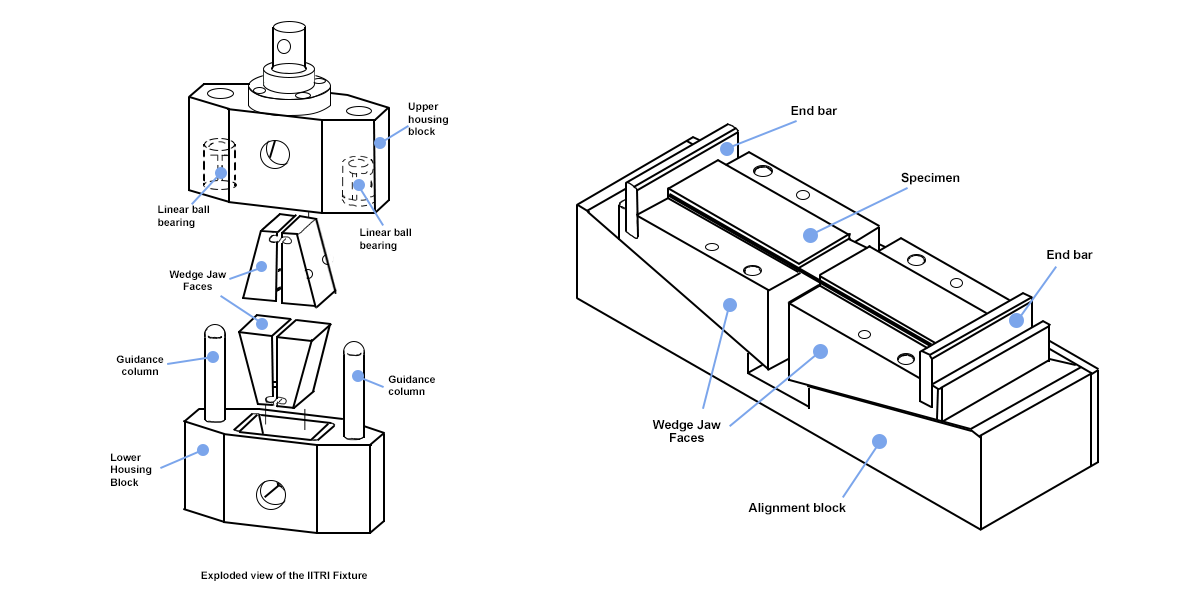

複合材料試験治具 - 圧縮

インストロンは、座屈防止ガイドプレートを使用しない複合材料用の圧縮試験治具を提供しています。複合材料の試験では、真の圧縮挙動を観察するため、ゲージ部を拘束しないこの方法が求められることがしばしばあります。