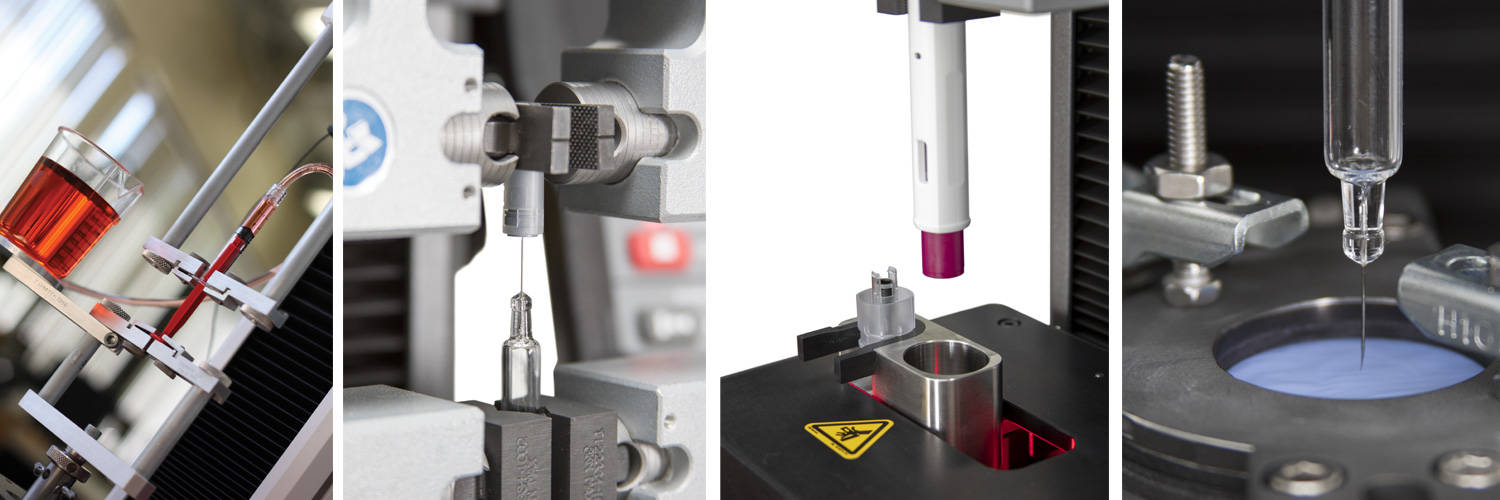

There have been increasing levels of interest in solutions for pharmaceutical products and mechanical testing of drug delivery systems, tablets, packaging, autoinjectors, luer locks, and syringes. Instron's torsion add-on allows an axial frame to add torsional capabilities and is ideal for applications that involve cap removal of vials and syringes, insertion and removal of dental or bone fixings, and activation of injector pens. Bluehill Universal’s Testprofiler allows single test actions to be repeated, helping to understand product behavior over a longer period. The sequence or properties of individual test actions can also be changed from step-to-step, allowing the test to be tailored to suit the operator's needs. Due to the demands of our current climate, another area of increased interest is the testing of PPE products such as gloves, gowns, masks and swabs.

For customers in industries where regulatory standards require traceability of all testing events, Instron can provide a software module for Bluehill Universal. Bluehill Universal’s Traceability Module achieves compliance through the seamless integration of electronic approvals, revision history, and an automated audit trail and provides a level of traceability that enables users to meet the audit requirements associated with FDA 21 CFR Part 11, ISO 17025, Nadcap, and others. This powerful add-on combines with Bluehill’s built-in security options to provide unmatched data traceability.

Plastics Testing

Though waste management concerns often result in plastics receiving bad press, this family of materials can be used to solve engineering problems and form products that would not be possible using other materials. Traditionally derived from oil, polymer manufacturers are now conducting research into using alternative raw materials that are more environmentally friendly. These alternatives still need to need to meet the performance afforded to oil-based polymers through standards such as ASTM D638, ASTM D790, ISO 527-2, and ISO 178.

Features:

- Automatic extensometry AutoX750

- Video extensometry AVE2

- Pneumatic grips

Most polymers are sensitive to temperature. To determine how they will perform at sub-ambient and elevated temperatures, an Instron environmental chamber can be used around the load string and specimen.

Elastomer Testing

Elastomers have helped to advance technology as much as any other material. Historical records suggest that the earliest uses of natural rubber would have been for waterproofing, adhesives, and sport balls. Today, elastomer use has grown to such an extent that they can now also be found in space, vehicles, domestic appliances, children’s toys, and buildings in addition to their original applications.

Elastomers are able to stretch or compress and return to their original shape, a property which lends itself to endless applications - but how do you test them? During a tensile test, elastomeric specimens elongate axially but contract across the width and thickness. If you were to use a gripping solution that was unable to compensate for this contraction in thickness, the specimen would slip from the grips. The correct way to grip elastomeric specimens is by using a mechanical self-tightening grip or pneumatic side-action grip with repeatable and constant gripping pressure.

Strain measurement for elastomers can also be a challenge depending on the application. For many standards, strength and displacement are used to determine the required results. When a strain measurement is required, consideration needs to be given to how the extensometer interacts with the specimen, as sharp knife edges are likely to initiate premature failure. Instron' solutions include a long travel extensometer as the entry level for elastomer strain measurement. The long travel extensometer uses lightweight arms with softened knife edges on a balanced mechanism. The knife edges remain in contact with the specimen through failure, allowing for the correct determination of strain at failure or peak load. For elastomeric materials that are sensitive to knife edge contact but require accurate strain measurement, either Instron's Standard or Advanced Video Extensometer can be used.

The elastomer family of polymers constitutes a wide spectrum. For those blends that exhibit some elasticity and traditional properties from thermoset or thermoplastic constituents, the high-throughput, high-accuracy AutoX750 may also be considered.